Monitoring Sand Erosion in Flowlines

Customer deployed the Inductosense WAND Thickness Monitoring Sensors (WAND-TM Sensors) to monitor wall thickness of offshore flowlines.

Overview

Client: Offshore Oil & Gas Operator

Date of Installation: September 2023

Asset: Flowlines including long-radius elbows, tine-ins and high-turbulence zones

Type of Degradation: Sand Erosion

Production in sand based environments are a common challenge in offshore oil and gas operations, leading to severe erosion risks in flowlines. Traditional inspection methods, such as manual ultrasonic testing (UT), require personnel deployment, can be costly, and can often have inconsistent data quality. To improve monitoring efficiency and reduce operational costs, the offshore operator deployed the Inductosense WAND Thickness Monitoring Sensors (WAND-TM Sensors) to monitor wall thickness of flowlines.

Challenges

• High costs and logistical difficulties in conducting frequent manual UT inspections on offshore platforms.

• Limited accessibility to erosion-prone areas, such as elbows and tie-ins without extensive scaffolding or shutdowns.

• The need for a reliable and cost-effective method to track erosion trends over time without disrupting production.

Solution

To address these challenges, 169 passive wireless sensors were permanently installed at strategic monitoring points across the operator’s offshore assets. The battery-free TM Sensors are activated using a data collector when in close proximity, by providing accurate wall thickness measurements from the same location each time.

Implementation Steps:

- Site Assessment: Historical loss of primary containment (LOPC) events and flow simulations were used to identify erosion-prone locations.

- Sensor Installation: Sensors were installed at targeted areas, including elbows, turbulence zones, and welds. Each sensor was coated for protection against harsh offshore conditions.

- Baseline Measurements: Manual UT and computed radiography were

conducted pre-installation for reference thickness values. - Data Collection: Measurements were taken over a two-year period to assess accuracy, efficiency, and cost-effectiveness.

Results

• Accuracy: Thickness measurements remained within a ±0.05 mm variation compared to reference UT data, ensuring high reliability.

• Efficiency: Measurement collection time was significantly reduced, allowing on-board personnel to perform inspections without the need for specialised UT technicians.

• Cost Savings: The implementation of passive sensors minimised the need for frequent manual UT inspections, reducing operational costs and preventing unplanned shutdowns.

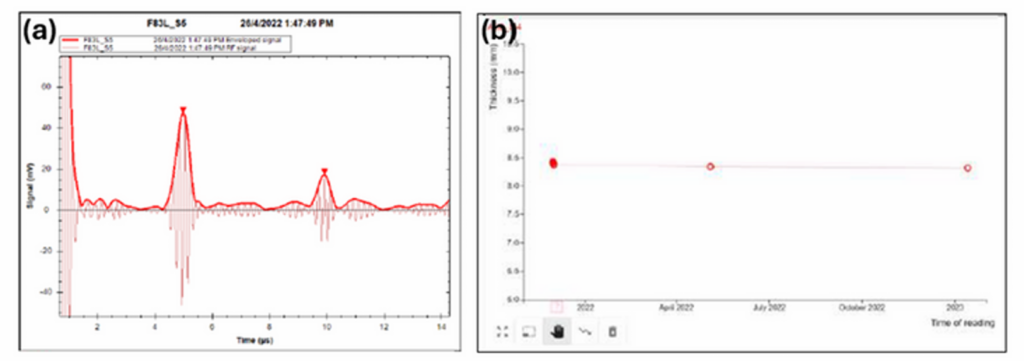

(a) A-scan from a sensor (location F83L_S5, date 26/04/2022) showing a time-traced reflected signal. The waveform and envelope are plotted.

(b) Thickness trend over one-year period for the sensor location.

Key Benefits

- The customer benefited from reliable and accurate wall thickness monitoring without frequent manual inspections.

- The deployment of passive wireless ultrasonic sensors provided the customer with cost-effective savings, compared to traditional UT and online monitoring solutions.

- Utilising embeddable sensors, efficiency is improved by enabling non-intrusive, real-time data collection.

- Safety is enhanced by reducing the need for personnel exposure in hazardous offshore environments.

- iDART facilitated early erosion detection, allowing for proactive maintenance planning, preventing costly repairs and production losses.

Conclusion

By deploying passive wireless ultrasonic sensors, the operator achieved a more cost-effective and efficient approach to monitoring flowline sand erosion in their offshore operations. This significantly reduced their reliance on manual ultrasonic testing, allowing them to enhance asset integrity management while minimising operational disruptions. As a result of these clear benefits, the operator is now recommending broader adoption of the technology across other high-risk erosion areas, especially in offshore locations where traditional inspection methods are logistically challenging.