Pipe Wall Thickness Monitoring Under a Permanent Corrosion Prevention Coating

The client needed to acquire monthly thickness measurements on pipework at an Oil & Gas terminal in Malaysia to monitor internal erosion caused by sand erosion.

Overview

Application: In-service internal corrosion monitoring of coated piping

Client: Confidential

Asset: Oil & Gas Terminal

Location: Onshore, Malaysia

The client needed to acquire monthly thickness measurements on pipework at an Oil & Gas terminal in Malaysia to monitor internal erosion caused by sand erosion. They also needed the same pipework to be protected against external corrosion with a permanent corrosion prevention coating. The solution outlined in this case study was a combination of the Inductosense WAND system and the Stopaq WrappingBand system.

Challenges

The application of a permanent coating to pipework to prevent against external corrosion in a very humid, hot and wet environment presented multiple challenges to conventional inspection methods. As such, an alternative approach was required.

- Frequent monitoring of the asset was required without the time consuming, costly and destructive removal of Stopaq that could cause moisture, air and bacteria ingress.

- The Stopaq coating inhibits ultrasonic propagation that can render traditional manual ultrasonic testing (UT) redundant.

- The permanent nature of polyisobutylene-based Stopaq coating required the thickness monitoring technology to be ultra low-profile, embeddable and wireless without impacting the coating protection performance.

Solution

The Inductosense WAND system and Stopaq WrappingBand system were combined to provide effective thickness monitoring under a permanent coating system.

Multiple WAND thickness monitoring (TM) sensors were installed on pipework to measure wall thickness. The sensors are less than 1mm thick and wireless and battery-free. WAND TM sensors were selected for their ultra-low profile, repeatable and accurate thickness measurements and low-cost.

The polyisobutylene-based Stopaq WrappingBand and high temperature polypropylene (HTPP) mechanical protection Outerwrap were applied over the WAND TM sensor. This permanent Stopaq coating system provided protection against external corrosion of the asset together with protecting the WAND TM sensor.

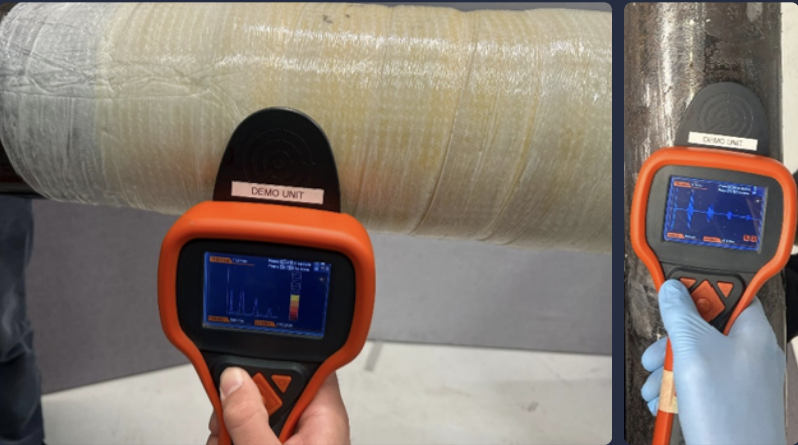

The WAND handheld data collector (WAND-HDC) was used to activate and wirelessly collect the ultrasonic signal from the installed WAND TM sensors through the Stopaq coating.

Inductosense iDART software was used to upload and analyse trends in the wall thickness data.

Implementation

The WAND system and Stopaq coating was installed by Inductosense's partner in the region, Nuri-Cerah Sdn Bhd.

- The client identified where the WAND TM sensors were to be installed based on pre-existing condition monitoring locations. After installation of the sensors the Stopaq WrappingBand and HTPP mechanical layer was applied as replacement to the existing coating. Due to the reduced surface preparation requirement (St2, wire brush) the coating could be applied quickly over the WAND TM sensors without having to surface blast or remove the existing coating.

- Due to Stopaq being a polymeric coating it was possible to power up the battery-free sensor and enable data transfer, through the coating, using the inductive-coupling from the WAND-HDC. Application of Stopaq in a concentric banding pattern enabled multiple measurement points and the asset external surface to be protected.

- By implementing the WAND solution under Stopaq WrappingBand our client was able to digitalise the collection and analysis of data by utilising the iDART cloud-based software. The software enables multiple users to access the uploaded data, view thickness trending (on a time-thickness (x-y) plot) and corrosion rate, simply from a web browser login. The easy access to data provided more informed decisions to scheduling future maintenance and inspection.

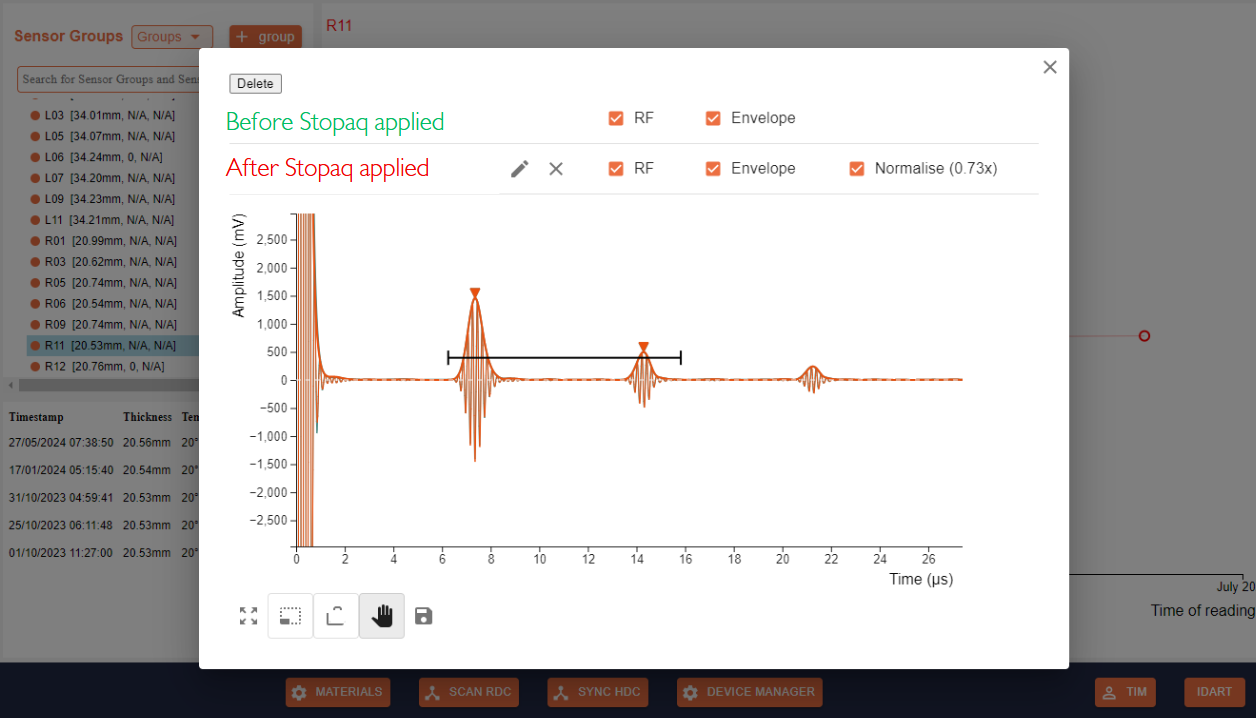

The iDART software can be used to accurately trend the wall thickness data from the multiple sensors over a period of time.

The iDART software enables analysis of the ultrasonic A-scan before and after application of the Stopaq WrappingBand over top of the sensor.