Transforming Risk Based Inspection Through Widescale Deployment of WAND

Our customer needed to monitor wall thickness across thousands of critical measurement locations (CMLs) at an oil & gas facility to improve Risk-Based Inspection (RBI).

Overview

Client: Oil & Gas Operator

Date of Installation: February 2026

Our customer required frequent, accurate wall thickness measurements across thousands of CMLs to enable reliable internal corrosion rate prediction and support data-driven RBI. The solution outlined in this case study demonstrates widescale deployment of the Inductosense WAND system, including remote, handheld, and robotic measurement solutions for Tier 1-3 CMLs.

Challenges

- Frequent, reliable monitoring without costly scaffolding, insulation removal, or highly skilled manpower.

- Access limitations at high, confined, or insulated locations increased inspection costs and personnel risk.

- Data consistency issues from manual ultrasonic testing (MUT), including variable calibration, repeatability, and measurement location inconsistencies.

Solution

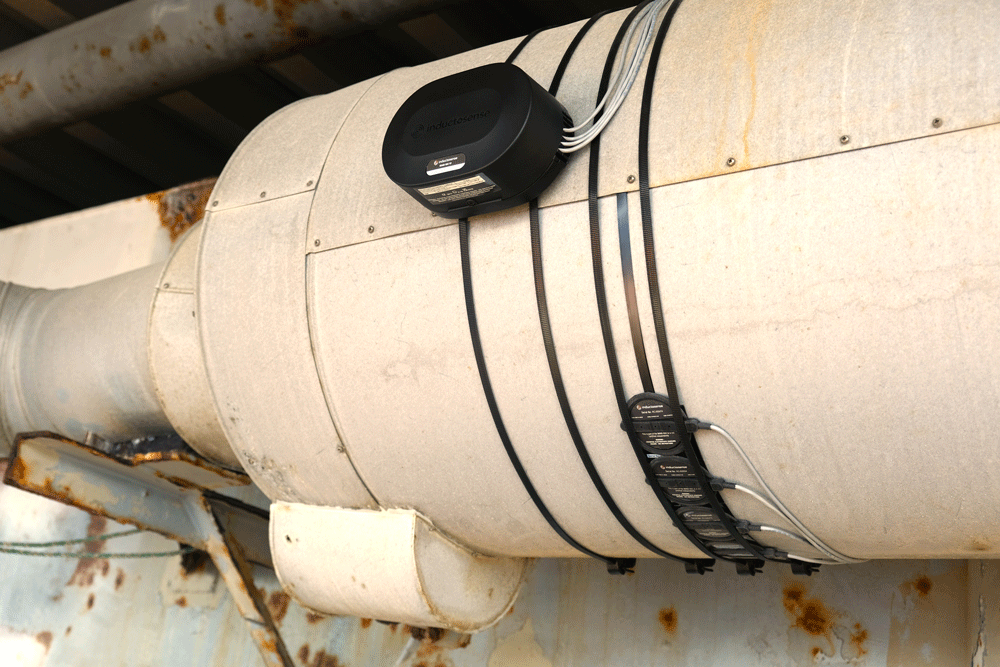

The Inductosense WAND solution provided permanent and repeatable wall thickness measurements using WAND Thickness Monitoring Sensors (TMS) across Tier 1–3 CMLs:

Tier 1 CMLs:

WAND Remote Data Collectors (RDCs) captured automated daily measurements. The ECHO accessory enabled readings through insulation without removal. Measurement frequency could be reconfigured at any time.

Tier 2/3 CMLs:

WAND Handheld Data Collectors (HDCs) with accessories such as the REACH measured hard-to-access locations. Robotic solutions, including drones and ATEX-rated robots, were also trialled.

Results

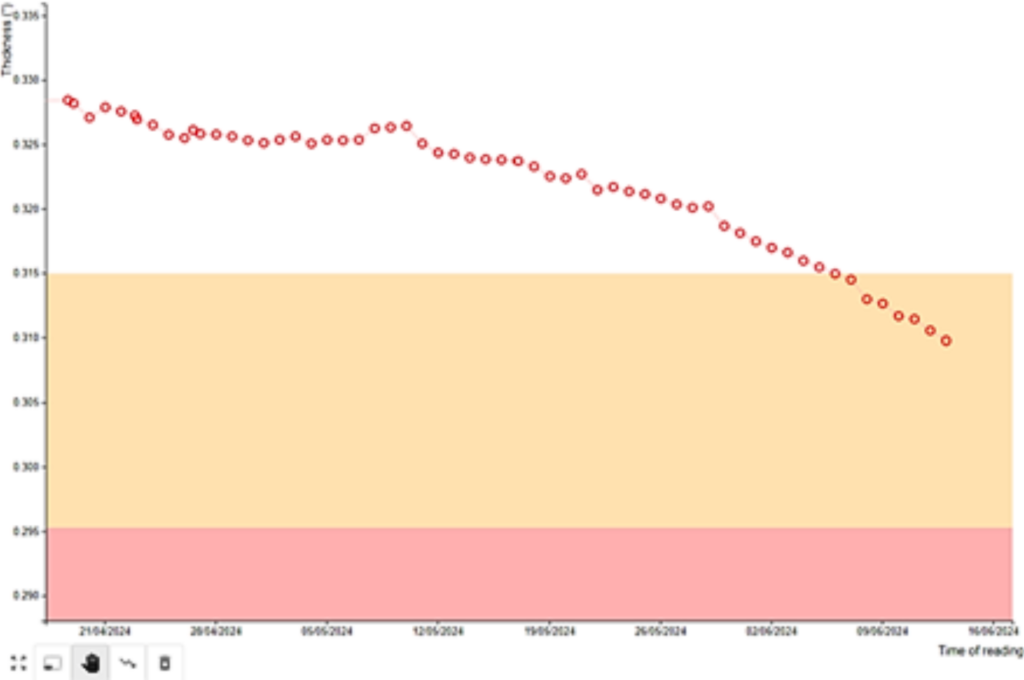

- Accurate and Repeatable Corrosion Monitoring: Daily WAND-RDC measurements over two months revealed an average corrosion rate of 3.1 mm/year, enabling immediate action based on short-term trends.

- Safety Improvements: Reduced personnel exposure in hazardous or hard-to-access areas through remote or robotic methods.

Key Benefits

- Accurate, repeatable wall thickness measurements across thousands of CMLs.

- Optimised inspection planning and data-driven RBI.

- Reduced inspection cost and personnel risk.

- Flexible measurement frequency and inspection method based on corrosion trends.

Conclusion

The widescale deployment of WAND technology transforms RBI by providing repeatable, fast, and accurate thickness measurements. Thousands of sensors per asset deliver cost-effective, data-driven inspection, enhance safety, and support proactive integrity management. Flexible deployment, including WAND-RDCs, WAND-HDCs, and robotic solutions, enables fully digitalised integrity programs and real-time risk assessment across Tier 1–3 CMLs.