What Could Shell Pearl GTL Lighthouse Project Mean for the Future of Corrosion Monitoring

Shell’s Pearl GTL plant in Qatar was recently recognised by the World Economic Forum as a Global Lighthouse, a distinction awarded to industrial sites that demonstrate exceptional digital transformation. Inductosense congratulate Shell Pearl GTL on this achievement in deploying over 45 4IR (Fourth Industrial Revolution) solutions, including advancements in integration and digitisation.

Within five years of applying these solutions, Shell Pearl GTL was able to increase their site throughput by 9%, improve reliability by 99%, cut emissions by 7% and extend equipment lifespan by up to 50%. This achievement showcases how digital technologies can drive improvements in reliability, sustainability, and safety at scale.

Read the press release from the World Economic Forum: Global Lighthouse Network 2025: World Economic Forum Recognizes 12 New Sites Driving Holistic Transformation in Manufacturing > Press releases | World Economic Forum

Digital Transformation Through NDE 4.0

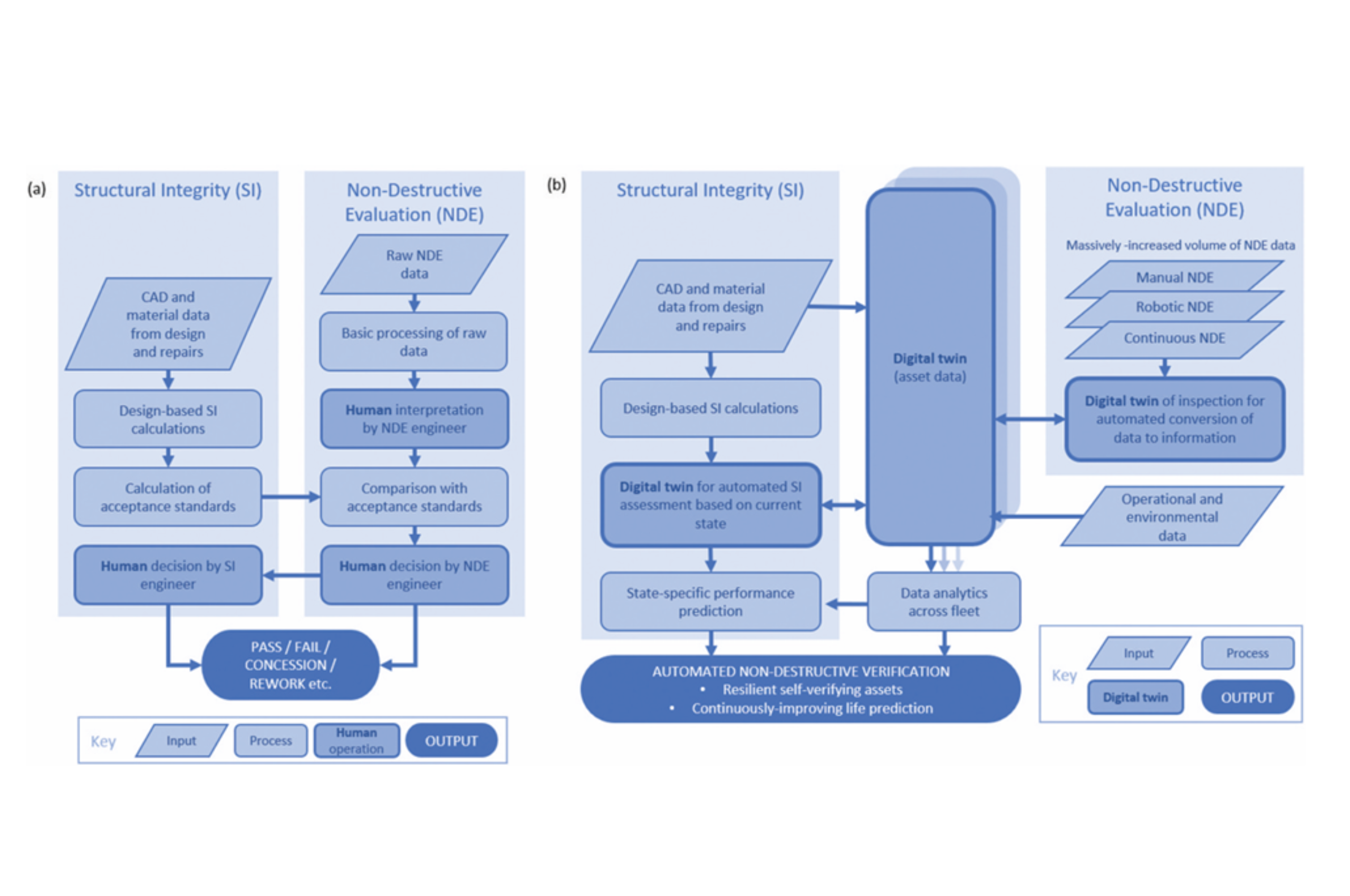

NDE 4.0 (Non-Destructive Evaluation 4.0) represents the digital transformation of inspection and integrity assessment within 4IR. It combines smart sensors, connectivity, automation, robotics, artificial intelligence, and data analytics to make inspection processes faster, more consistent, and data-driven.

By enabling continuous data collection and analysis, NDE 4.0 shifts integrity management from reactive to predictive, supporting safer operations and more efficient maintenance. It provides a foundation for connected asset infrastructure where insights can be shared in real-time across teams and sites.

Learn more about NDE 4.0 through this technical paper by Inductosense cofounder Paul Wilcox: “Advances in the UK toward NDE 4.0.”

View Technical Paper

Inductosense's Approach to NDE

Inductosense aligns with the principles of NDE 4.0 and 4IR solutions, to make corrosion monitoring accurate, scalable and fully digitalised. Our WAND Solution integrates smart wall-thickness monitoring sensors (WAND-TMS) seamlessly with existing infrastructure, to monitor corrosion at critical monitoring locations across an asset.

Utilising the connectivity and automation of WAND Remote Data Collectors and WAND-Online Gateway, accurate and repeatable data is collected from the installed WAND-TMS. This data is visualised within iDART’s data analytics dashboard, enabling informed decision making, extended asset life, and improved safety.

Autonomous and remote data collection is at the forefront of our future developments, through joint industry projects with ExR for robotic integration and Deepstar for subsea applications. These collaborations aim to enable fully automated inspection and remote data collection, extending the reach of the WAND Solution to challenging and inaccessible environments.

We are also closely working on integrating our data with advanced AI models as jointly presented in the Oman Corrosion and Materials Conference shell titled “Corrosion Monitoring and Machine Learning: Revolutionizing Integrity Management” For more information on this presentation feel free to get in touch.

Advancing Scalable and Data-Driven Integrity Management

With many customers already deploying the WAND Solution across their assets, Inductosense is proud to be part of the shift toward fully integrated, data-driven, and scalable integrity management.

The success of Shell Pearl GTL Lighthouse project represents a major milestone in the reliability of fully integrated, digital, and proactive integrity management. Building upon this foundation, Inductosense will continue to develop technology and solutions that seamlessly integrate into existing systems, supporting the industry’s shift toward predictive and autonomous integrity management.

Discover how the WAND Solution can transform your approach to asset integrity by enquiring today.

Enquire